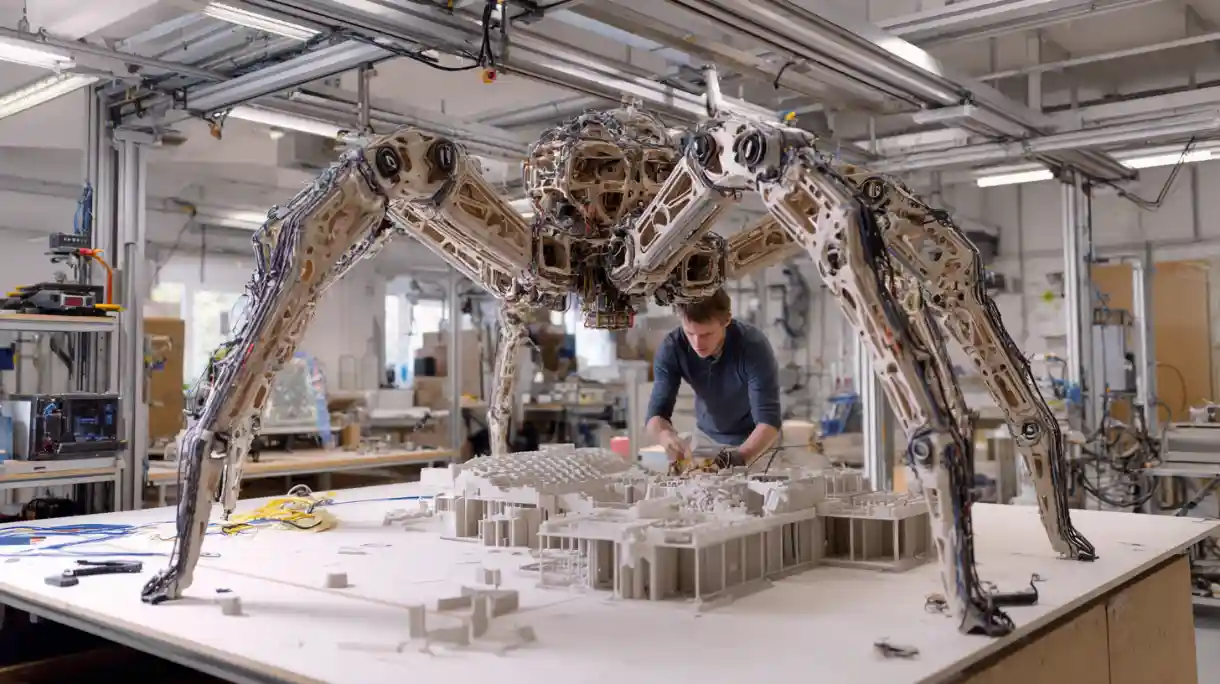

Spider Robot 3D-Prints Homes in Under 24 Hours

Spider Robot Can 3D-Print a House in 24 Hours – The Future of Construction?

In Brief

- • A spider-like robot named Charlotte can 3D-print full-size homes in ~24 hours using local earth materials.

- • The system cuts costs, emissions, transport, and labor demand.

- • Safety certifications, code compliance, and structural testing remain major hurdles before mainstream adoption.

A spider-legged robot in Sydney is now capable of 3D-printing a house in just one day. Using nothing but compacted earth, sand, and clean waste from the build site. If the system scales, it could fundamentally reshape how we build homes, especially in regions under extreme housing pressure.

Instead of relying on truck-delivered concrete or factory-made blocks, Charlotte prints layered, compacted earth structures on location. This removes a large portion of the energy-intensive manufacturing pipeline that traditional materials require, while also cutting transport emissions and simplifying logistics.

According to a report from November 17, The system’s legged design allows it to work on uneven terrain, something wheeled or rail-based 3D printers struggle with, making it a more adaptable tool for real-world construction sites.

Earthbuilt Technology co-founder Dr. Jan Golembiewski, who leads the project, says the robot could one day match the output of “over 100 bricklayers.” If that estimate holds true at scale, Charlotte could provide a fast-deployable solution for regions facing severe housing demand or mounting construction backlogs.

It could also support remote areas where material transport is costly or disaster zones where rapid rebuilding is critical.

This Could Change How We Build Homes

Notably, Charlotte’s process focuses on extrusion-based earth printing, a method that pushes material through a nozzle to form continuous courses without mortar joints.

According to UN data, buildings account for 37% of global construction-related CO2 emissions, and avoiding cement manufacturing would cut a core source of early-stage emissions.

The approach also raises workforce questions. In regions with skilled-labor shortages, such machines could ease pressure, but in markets where construction is a primary income source, automation may require new training and policy support.

Safety testing and code compliance remain major hurdles as structural performance must be validated across diverse soil mixes, climates, and building standards. Developers say digital mix-adjustment systems could compensate for material variability, but this will require independent verification.

Meanwhile, the platform is conceptually much like the recent breakthrough in which Chinese scientists have managed to develop the first-ever 3D printing system that uses lunar regolith – materials already on the Moon, effectively taking out of the equation the need for Earth-sourced construction materials.

More Must-Reads:

How do you rate this article?

Subscribe to our YouTube channel for crypto market insights and educational videos.

Join our Socials

Briefly, clearly and without noise – get the most important crypto news and market insights first.

Most Read Today

Peter Schiff Warns of a U.S. Dollar Collapse Far Worse Than 2008

2Samsung crushes Apple with over 700 million more smartphones shipped in a decade

3Dubai Insurance Launches Crypto Wallet for Premium Payments & Claims

4XRP Whales Buy The Dip While Price Goes Nowhere

5Luxury Meets Hash Power: This $40K Watch Actually Mines Bitcoin

Latest

Also read

Similar stories you might like.