A car with a broken windshield

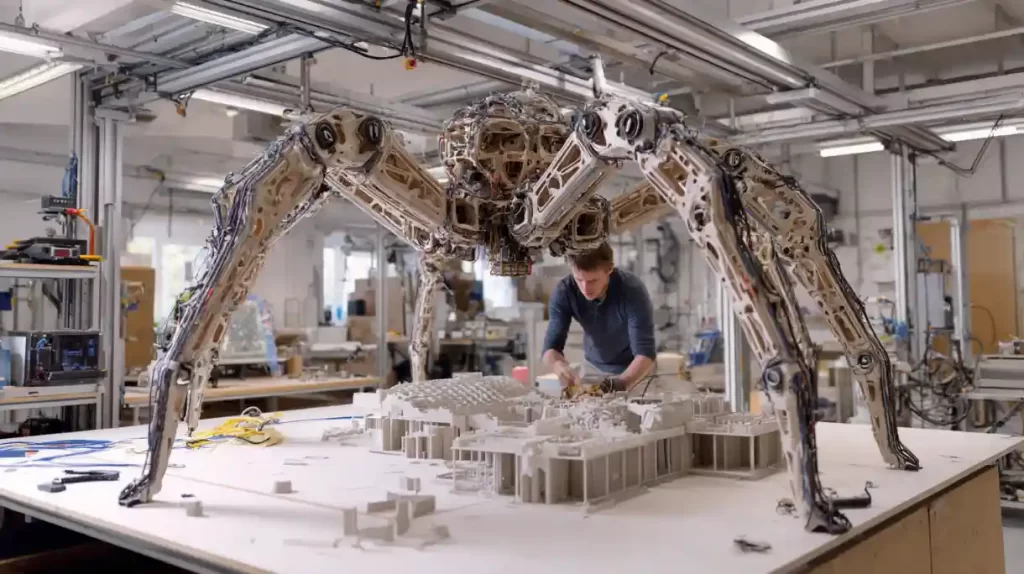

3D-printed materials have been used for many purposes including safety in vehicles, but a new discovery shows potential for higher safety.

Scientists at the University of Glasgow on 24 October published the findings of research revealing that a new form of 3D-printed material can better mitigate the effects of impact in vehicles.

Taking 3D further

Before now, there was the use of 3D materials to minimize the impact of crashes in vehicles.

However, such materials were quite primitive, making them less effective in protecting passengers.

The new ‘adaptive twisting metamaterials’ represent an entirely different approach to protecting passengers in accident situations.

With a unique lattice shape that allows it to twist, the materials can be mechanically controlled to respond according to the amount of impact rather than give the same amount of resistance in all situations.

When an external force acts on it, the material can be compressed and twisted into a corkscrew-like motion, absorbing the impact energy.

They were found to absorb the most energy when constrained from twisting at all, and the rate of absorption reduced with more twisting allowed.

Real-world applications

The researchers see the technology finding application in any machine that needs protection from crashes.

Professor Shanmugam Kumar of the University of Glasgow’s James Watt School of Engineering who led the research said:

“We believe the material could find applications in both automotive and aerospace safety in the future, providing a single new class of material capable of adapting to different needs as required. It could also support the development of novel forms of energy harvesting, by converting impacts into rotational kinetic energy.”

Real-world tests of the technology are further done using a comprehensive theoretical and computational model that accurately predict the behavior of the material in different conditions.

Researchers from the Polytechnic University of Marche, the University of L’Aquila and the National Institute for Nuclear Physics in Italy contributed to the research

How do you rate this article?

Subscribe to our YouTube channel for crypto market insights and educational videos.

Join our Socials

Briefly, clearly and without noise – get the most important crypto news and market insights first.

Most Read Today

Samsung crushes Apple with over 700 million more smartphones shipped in a decade

2Peter Schiff Warns of a U.S. Dollar Collapse Far Worse Than 2008

3Dubai Insurance Launches Crypto Wallet for Premium Payments & Claims

4XRP Whales Buy The Dip While Price Goes Nowhere

5Luxury Meets Hash Power: This $40K Watch Actually Mines Bitcoin

Latest

Most Read Today

MOST ENGAGING

Also read

Similar stories you might like.