BMW expands its Virtual Factory with AI; Here’s why it matters

BMW expands its Virtual Factory with AI; Here’s why it matters

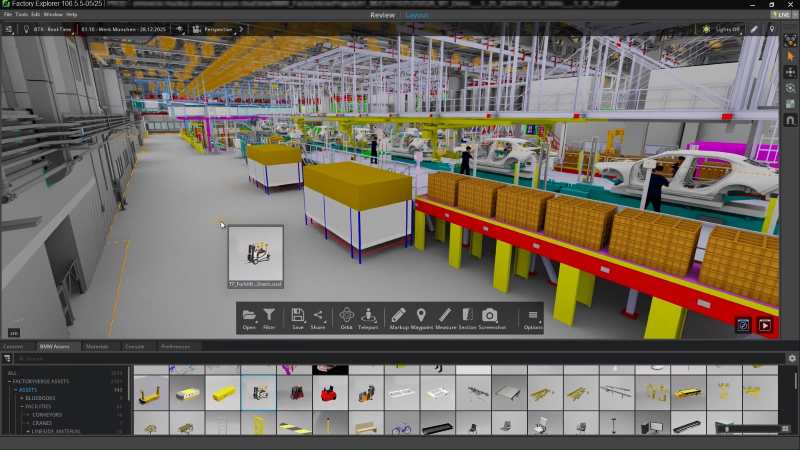

As the automotive industry continues to keep up with the times, especially in terms of technology, BMW Group has scaled its Virtual Factory with more innovative solutions, including generative and agentic artificial intelligence (AI) capabilities.

Specifically, BMW is industrializing its iFACTORY, which involves consistently scaling applications in the digital twins of more than 30 production sites to enhance production planning around the world, according to the company’s press release from June 11.

What BMW’s Virtual Factory provides

Indeed, the brick-and-mortar plants, represented by their digital twins, will make use of the wide selection of tools to provide virtual planning through intelligent linking of building data, equipment data, logistics data, as well as 3D simulation of manual work processes.

These tools include an industrial 3D metaverse application based on NVIDIA Omniverse, where simulations can take place in real-time, enabling virtual optimization of layouts, robotics, and logistics systems, consequently reducing production planning costs by up to 30%.

Furthermore, BMW’s Virtual Factory facilitates digital, automated, and quick checks, using construction data combined with 3D scans, precisely simulating the movement and rotation of a vehicle through the production lines to make sure that all the new products fit the production line and don’t collide with its surroundings at any point.

As such, the company has reduced almost four weeks of real-world testing, during which the staff had to manually guide a real vehicle body through the production lines to identify potential collisions and sometimes even empty and clean the dip coating tanks, to only three days of virtual simulation.

Earlier in April, BMW launched an AI pilot project to catch vehicle defects before they hit the road. Notably, it consists of an AI system and learning-based analysis tool for customized quality checks in vehicle assembly, analyzing not just vehicle data, but massive amounts of other information, like the model and equipment variants, as well as real-time production data for each specific vehicle.

How do you rate this article?

Subscribe to our YouTube channel for crypto market insights and educational videos.

Join our Socials

Briefly, clearly and without noise – get the most important crypto news and market insights first.

Most Read Today

Samsung crushes Apple with over 700 million more smartphones shipped in a decade

2Peter Schiff Warns of a U.S. Dollar Collapse Far Worse Than 2008

3Dubai Insurance Launches Crypto Wallet for Premium Payments & Claims

4XRP Whales Buy The Dip While Price Goes Nowhere

5Luxury Meets Hash Power: This $40K Watch Actually Mines Bitcoin

Latest

Also read

Similar stories you might like.